small wastewater treatment plants

- for private households, gastronomy and trade up to 50 population equivalents complete systems in plastic or concrete design for retrofitting existing pits (retrofit kit) also suitable for holiday homes

As a specialist company for the maintenance of small sewage treatment plants, we know all types of small sewage treatment plants and will support you from expert advice, selection, installation and commissioning to regular maintenance and long-term support, including sludge disposal. Please get in touch with one of our contact persons, we will advise you individually on your request. Our customers are distributed throughout Germany, which enables our employees to be ready to work quickly. In our in-house laboratory we can carry out the officially required analysis for self-monitoring and also further analyzes for the assessment of the water and operating properties in order to optimally support your system.

Modern sewage treatment systems out of conviction

Our company philosophy is to achieve the best possible cleaning performance, conserve resources, avoid emissions and achieve sustainable, high-quality operation. Basically, our small sewage treatment plants meet the highest German cleaning standard, effluent class D. In addition to CE and DIBt-approved systems from quality manufacturers, we also use our own models for this and rely on intelligent process control, durable components and the odorless humification of aerobically stabilized activated sludge.

BioTopp small wastewater treatment plant

With the development of the innovative BioTopp system with sludge soiling, odor nuisance and cost-intensive sewage sludge disposal have been a thing of the past since 1997. Since 2012, the system has been further improved with modern control technology. As a result, today it is the only plant capable of carrying out a process-engineered denitrification and a process-engineered biological phosphorus elimination in addition to the extensive degradation of the organic carbon compounds and a complete nitrification. Thanks to the intelligent cycle control, the system also survives temporary overloads, such as those that occur at family celebrations, and can also be used in holiday homes thanks to the ventilation adjustment.

The BioTopp system is a modified two-stage SBR process with an upstream optional aerobic denitrification reactor with integrated buffer storage, a self-cleaning raking or screening device and an obligatory aerobic sequential batch reactor (SBR). The aerobically stabilized and coarsely screened excess activated sludge is earthed as a thin layer on a drying bed, washed and sanitized by the weather and mineralized by biological degradation. In a four-person household with a conventional primary treatment system, approx. 1.5 - 6.0 m³ faecal sludge is produced, which usually has to be taken to the municipal sludge treatment facility by a disposal company every year (approx. 40 - 120 €/m³ sludge plus transport costs for suction vehicle). In comparison, the BioTopp system produces only 1 - 4 kg of sludge per inhabitant per year, which can be taken away cheaply in the course of regular maintenance.

advantages

- Lower investment costs for containers, excavation and transport, due to the 30 - 60% lower reactor volume than in conventional single-stage SBR plants. Odorless operation and significantly longer concrete service life thanks to aerobic process control, which also means that no faecal sludge and no hydrogen sulfide are produced. €200 - €500 € Annual operating cost savings thanks to BioTopp sludge humification, as no faecal sludge has to be removed with a vacuum truck. Best biological cleaning performance through nitrification (cleaning class N) and denitrification (cleaning class D). Increased biological phosphate elimination without the use of chemical precipitants (cleaning class P)

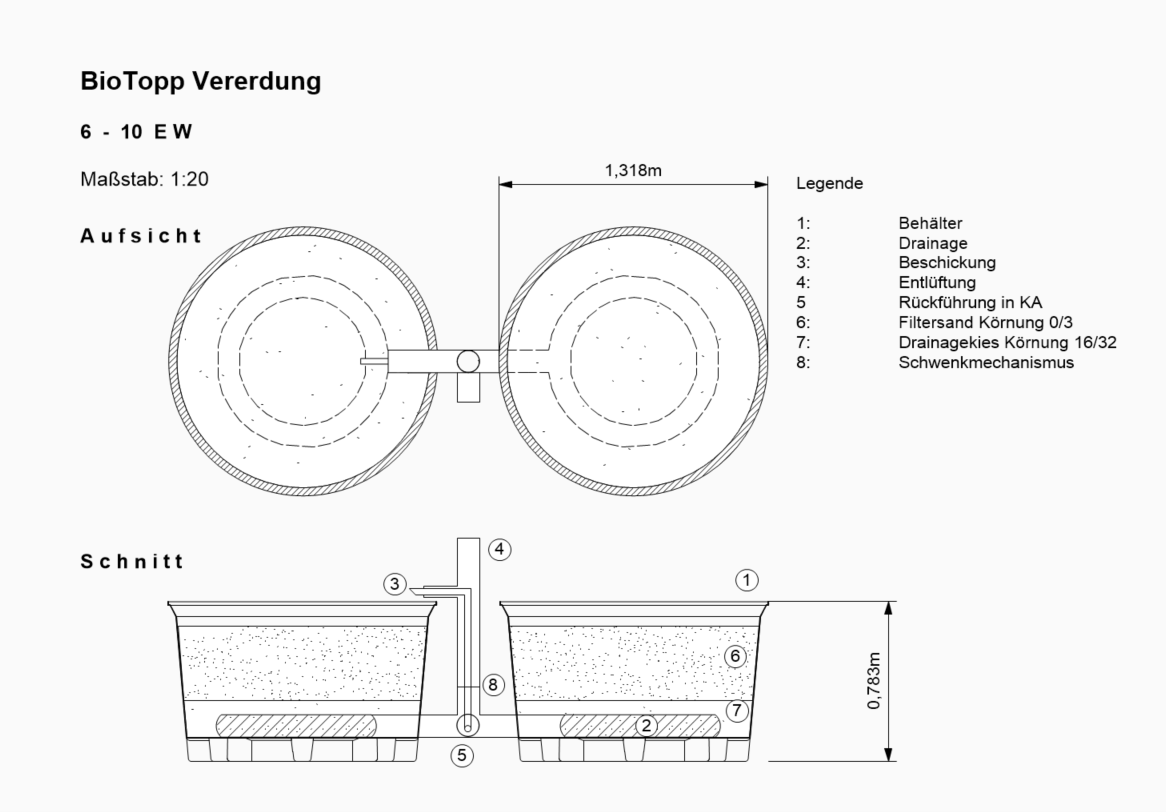

BioTopp - sewage sludge humification

Extension module for small wastewater treatment plants with aerobic activated sludge stabilization

- the cost-saving alternative to sewage sludge removal improved nutrient elimination to protect water bodies less greenhouse gas emissions and less energy requirements suitable for recycling

As a maintenance company and manufacturer of small sewage treatment plants, we have developed a process that allows your fully biological small sewage treatment plant to be operated with virtually no waste.

The BioTopp VE soiling stage is an expansion module that supplements the BioTopp sewage treatment plant system and plants with activated sludge stabilization. The product of mud soil is dried mud soil, which can also be used as a fertilizer for shrubs and ornamental gardens. The content of the soil basin consists of a lower drainage layer and an overlying layer of sand, on which plants can also be established. When excess sludge is drawn off, one of the two chambers of the siltation basin is charged. Subsequent seepage leads to dewatering of the sludge. An additional reduction in volume is achieved by exposure to the sun (formation of palm-sized flakes on the surface of the pool, thickness 3-5 mm). In addition, weathering and biological degradation cause the sludge to become sanitized. After about half a year (spring-autumn) or a year (autumn to autumn), the dried sewage sludge soil can be removed from the first chamber.

Further products:

- Container and compact sewage treatment plants

- Sewage lifting plants and pumping stations

- Neutralization systems and dosing stations

- Physical and biological fat separators

- Class I and II oil, petrol and light liquid separators

- Mechanical and physical cleaning

- Lamella separator and secondary clarification